Corian Manufacturing

- Home

- |

- Corian Manufacturing

Introduction to Corian Manufacturing: Crafting Excellence in Solid Surfaces

Corian, a renowned solid surface material, has gained widespread popularity for its versatility, durability, and aesthetic appeal. The manufacturing process of Corian involves a meticulous combination of advanced technology and craftsmanship. As a solid surface, Corian is composed of acrylic polymer and natural minerals, creating a seamless and non-porous material suitable for countertops, sheets, and various applications. In this article, we delve into the intricacies of Corian manufacturing, shedding light on the countertop, sheet, and solid surface manufacturing processes.

Corian Countertop Manufacturers: Crafting Functional Elegance

Corian countertops have become synonymous with elegance and functionality in modern kitchen and bathroom designs. The manufacturing of Corian countertops involves a multi-step process. First, a blend of acrylic polymer and natural minerals is mixed to create a homogenous material. This mixture is then shaped and molded into the desired countertop dimensions. The result is a seamless and non-porous surface that resists stains and offers endless design possibilities.

Leading Corian countertop manufacturers employ state-of-the-art technologies, ensuring precision in cutting, shaping, and finishing. CNC (Computer Numerical Control) machines play a crucial role in achieving intricate designs and custom shapes, allowing homeowners and designers to personalize their spaces with unique countertop creations. The final step involves polishing the surface to enhance its aesthetic appeal and provide a smooth, easy-to-maintain finish.

Corian Sheet Manufacturers: Transforming Raw Materials into Versatile Surfaces

Corian sheets serve as a foundation for a variety of applications, from wall cladding to furniture design. The manufacturing process of Corian sheets begins with carefully measured proportions of acrylic polymer and natural minerals. This mixture is then transformed into large, flat sheets using specialized machinery. The sheets are cured to achieve stability and uniformity in thickness.

Corian sheet manufacturers focus on quality control throughout the production process to ensure consistency in color, texture, and performance. These sheets offer flexibility in design, allowing architects and designers to explore innovative applications in residential and commercial projects. Whether creating sleek kitchen islands or dynamic wall panels, Corian sheets provide a durable and aesthetically pleasing solution.

Corian Solid Surface Manufacturers: Innovation in Seamless Integration

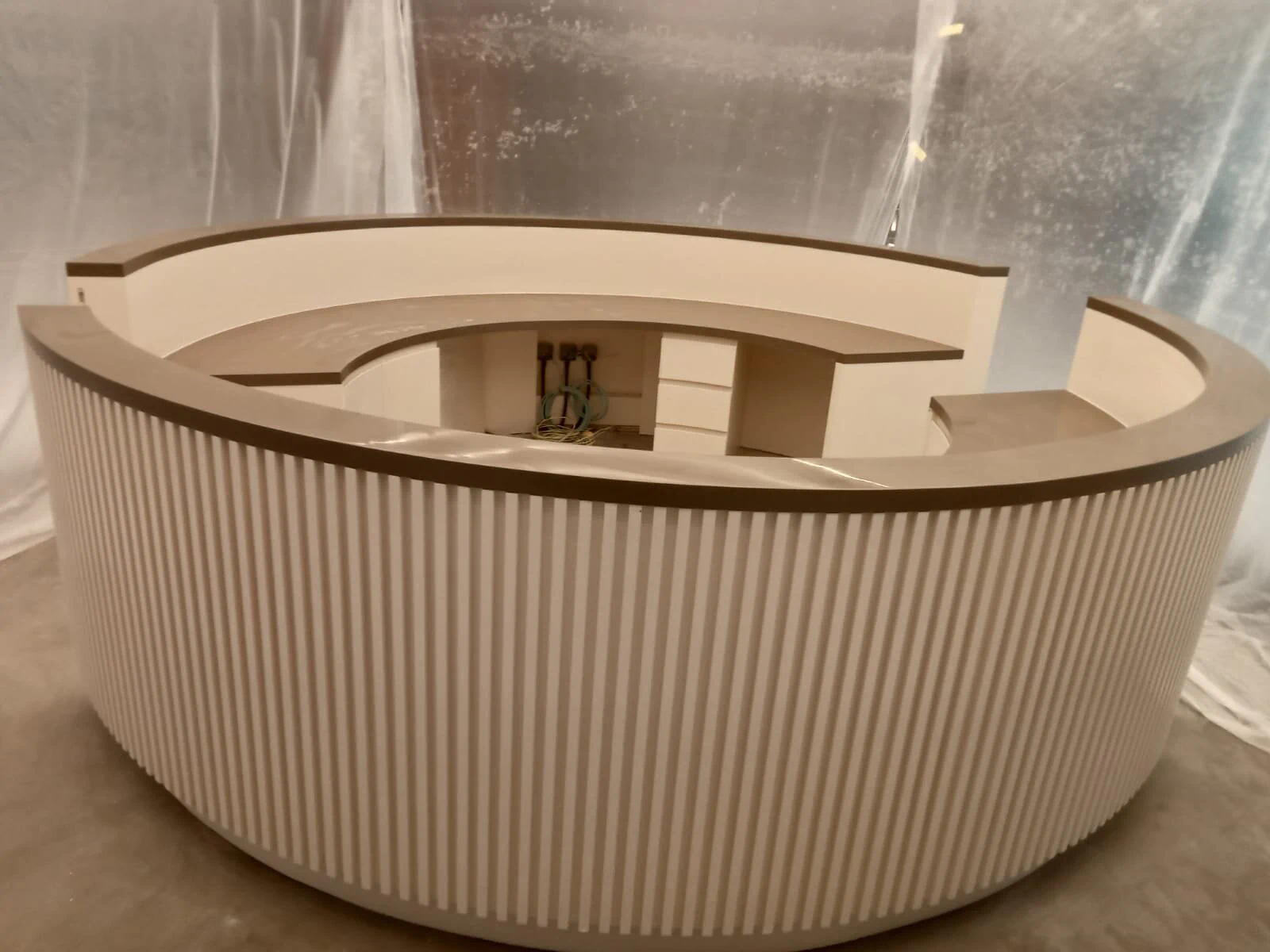

Corian's solid surface manufacturers play a pivotal role in creating seamless and visually appealing surfaces for a wide range of applications. The manufacturing process involves thermoforming, allowing for the creation of curved and three-dimensional shapes. This versatility makes Corian solid surfaces a preferred choice in interior design, healthcare, hospitality, and more.

Corian's solid surface manufacturing involves precise temperature control and expert craftsmanship to achieve flawless results. The material's non-porous nature makes it hygienic and easy to clean, meeting the stringent requirements of various industries. From reception desks to laboratory workstations, Corian solid surfaces combine aesthetics with functionality, showcasing the ingenuity of modern manufacturing techniques.